Is your sewing machine not working properly? If you tried every solution you can find on the internet and nothing worked, try these solutions by Jack Creek Road. He will tackle the most common issues everyone encounters when using a sewing machine. Do not give up just yet and give it away, as these may solve your problem/s.

RELATED: 7 Beginner Sewing Mistakes To Avoid

He tackled several sewing machine problems in the video below, but I only listed a couple. If your issue is not on the list, watch the whole video. He also gave a full explanation for each one so you can easily fix your sewing machine without asking for professional help.

Check this article as well: 3 Pro Tips For Taking Care of Your Sewing Machine

How to Fix a Sewing Machine

Spool pins

If you are using a vertical spool, you need to be using a spool felt. It will give the spool a nice smooth surface to pull off of.

Stacked Versus Cross Wound Thread

There are different types of spools.

- A cross-wound spool is designed to run horizontally.

- A stacked spool‘s thread easily falls off of the bottom. To avoid this from happening, use a spool net.

Spool Caps

The rule of thumb is to use a larger cap than your spool thread. It provides a smooth surface for the thread to pull off of. Don’t push it too far against and away from the pool.

Spool Cones or Spacers

If your spool is too large and running into the machine use a thread stand. If it’s too big for a vertical pin, get thread cones or spacers to fill the gaps.

Thread Quality

If you have a high-performance sewing machine, do not buy the cheapest thread in the market.

Upper Tension

Make sure you have a spool felt underneath your spool if you’re running a vertical pin or a spool cap larger than your pool if you are running a horizontal pin.

There should be an indicator of what your tension should be most of the time. Machines may have a center mark, or dot, or may be highlighted in a different color to differentiate from other tensions. Start there when troubleshooting.

Your presser foot should be in the up position when you are threading.

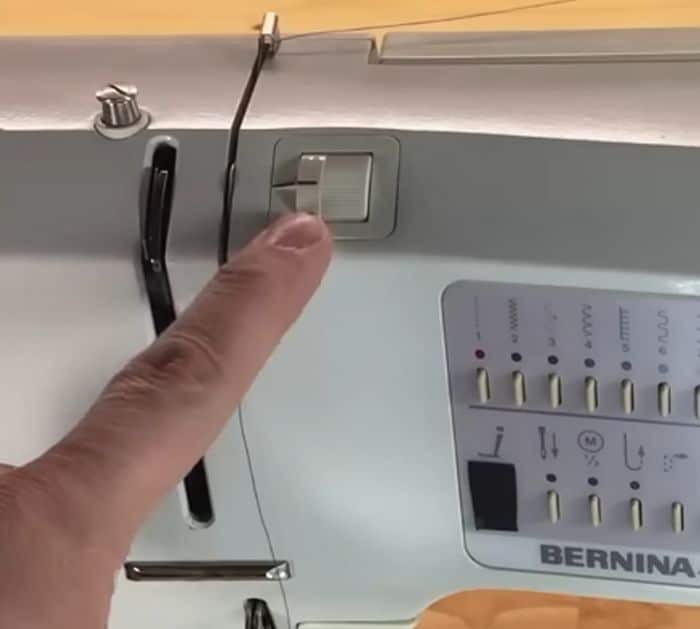

Loops on the Bottom (Missing The Take-Up Lever)

The take-up lever pulls the slack out of each stitch.

If it’s jammed, move the take-up lever to the highest position, lift the presser foot(you can do it in some machines), open the bobbin door, pull down the race, and grab the bobbin case and the hook. Cut the thread.